4 weeks

spring '24

sketching

CAD modeling

woodworking

Four-Board Poplar Stool

With a 60" long plank of unfinished Poplar, I designed, modeled, processed, cut, and assembled a four-board stool.

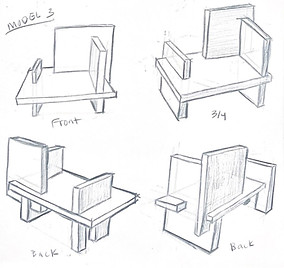

Rough Prototypes

Table of Contents

Rough Prototypes

To freely and quickly experiment with different designs, I created 1/4 scale stools out of foam core board.

The unprocessed plank of poplar was 60" x 11" x 1".

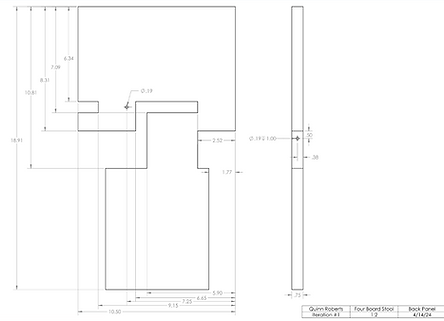

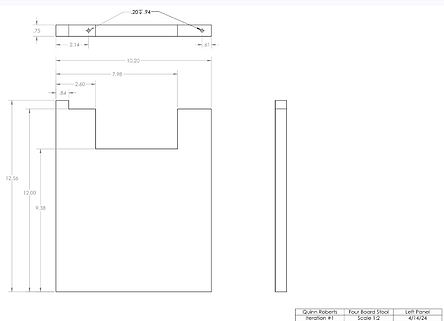

SolidWorks Models

I measured features of the foam core models that worked well and adapted them to SolidWorks. I continued to adjust and iterate digitally. Below is an exploded view of the stool assembly.

I wanted the design to feature a variety of joint types, including slip and dado, while also accounting for a consistent flow in the direction of grain, and a balance of negative space. I also ensured that there would be enough stability in the design by accounting for screw placement

Construction

I used a chop saw to get my planks to their proper size, then joined and planed the wood until it was the proper thickness and square. For individual pieces I used the bandsaw and router to cut internal grooves, and a chisel to create internal corners.

Assembly

To assemble the panels, I drilled holes in the panels and attached panels with Robertson screws. I used the drill press to create plugs from contrasting Spanish Cedar, and used those to fill the screw holes and highlight the production process. I sawed off excess Spanish Cedar to lay flush to the Poplar.

The stool backrest is 19" tall, with the seat 12.5" off the ground. I chose specific portions of the plank to be used in order to emphasize the grain flow and create a cohesive stool with a balance of negative space.

Final Stool